Unlocking Efficiency: The Essential Role of ECU Control Box Assembly in Modern Agricultural Machinery

Release time:

2025-06-05

Unlocking Efficiency: The Essential Role of ECU Control Box Assembly in Modern Agricultural Machinery

Table of Contents

- 1. Introduction to ECU Control Box Assembly in Agriculture

- 2. Understanding ECU Technology in Agricultural Machinery

- 3. Key Components of ECU Control Box Assembly

- 4. Benefits of ECU Control Box in Agricultural Applications

- 5. Impact of ECU Control Boxes on Efficiency and Productivity

- 6. Future Trends in ECU Technology for Agriculture

- 7. Common Issues and Troubleshooting ECU Control Boxes

- 8. Conclusion

- 9. FAQs about ECU Control Box Assembly in Agriculture

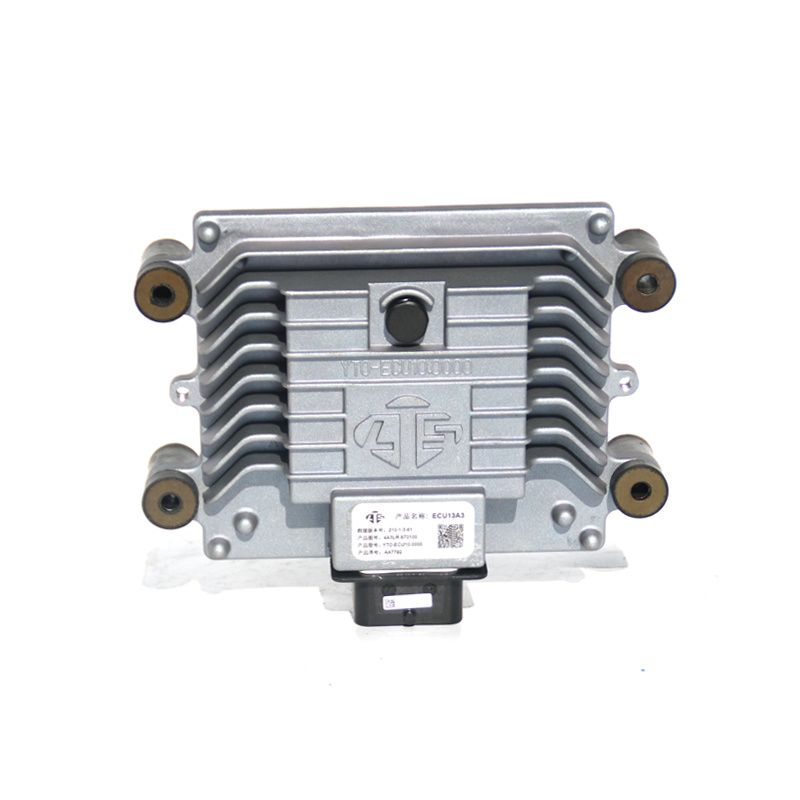

1. Introduction to ECU Control Box Assembly in Agriculture

In the realm of modern agriculture, efficiency is paramount. The incessant demand for higher yields coupled with the need for sustainable practices has pushed farmers to seek innovative solutions. One such development is the ECU (Electronic Control Unit) control box assembly. This vital component serves as the brain of agricultural machinery, controlling various functions and assisting in seamless operations. In this article, we will delve into the intricacies of ECU technology, its benefits, and how it is reshaping the agricultural landscape.

2. Understanding ECU Technology in Agricultural Machinery

The Electronic Control Unit (ECU) is an embedded system within agricultural machinery that manages and regulates the operations of the equipment. By utilizing sensors and microcontrollers, the ECU interprets data regarding various aspects such as engine performance, fuel efficiency, and equipment operation.

**Key Functions of ECU Technology**:

- **Data Collection**: The ECU gathers data from multiple sensors placed throughout the machinery, monitoring key parameters such as temperature, pressure, and speed.

- **Real-time Processing**: It processes this data in real-time to make instantaneous decisions that enhance operational efficiency.

- **Control Commands**: Based on the processed information, the ECU sends commands to various actuators to adjust settings and optimize performance.

3. Key Components of ECU Control Box Assembly

To fully grasp the functionality of an ECU control box, it is essential to understand its core components. Each part plays a crucial role in ensuring the smooth operation of agricultural machinery.

3.1 Microcontroller

The microcontroller acts as the brain of the ECU, executing instructions and processing data. It is responsible for managing the inputs from various sensors and generating outputs to control other machinery components.

3.2 Input/Output Ports

These ports allow communication between the ECU and the external environment. Input ports receive data from sensors, while output ports send commands to actuators and other devices.

3.3 Power Supply

The power supply unit ensures that the ECU and its components operate efficiently. It converts the vehicle's battery power into the necessary voltage levels for the ECU to function.

3.4 Sensors

These devices collect critical data, such as engine temperature, fuel level, and hydraulic pressure. The ECU interprets this data to make informed decisions regarding machinery operations.

3.5 Actuators

Actuators receive commands from the ECU to perform specific actions, such as adjusting throttle position or activating hydraulic systems. They play a crucial role in translating the ECU's decisions into mechanical actions.

4. Benefits of ECU Control Box in Agricultural Applications

The implementation of ECU control box assemblies in agricultural machinery provides numerous advantages:

4.1 Enhanced Precision

With real-time data processing, ECU technology allows for precise control of machinery functions, ensuring optimal performance tailored to specific field conditions.

4.2 Increased Fuel Efficiency

By monitoring engine performance and adjusting fuel delivery accordingly, ECUs help in managing fuel consumption, leading to significant cost savings for farmers.

4.3 Improved Equipment Longevity

The ECU can identify potential issues before they lead to severe damage, allowing for timely maintenance and repairs, which ultimately extends the lifespan of the equipment.

4.4 Reduced Environmental Impact

With better fuel efficiency and precise operations, ECU technology contributes to reduced emissions and less environmental degradation, aligning with sustainable farming practices.

4.5 Automation and User-Friendly Interfaces

Many modern ECUs come equipped with user-friendly interfaces, enabling farmers to automate tasks and reduce manual labor, further improving productivity and efficiency.

5. Impact of ECU Control Boxes on Efficiency and Productivity

The integration of ECU control box assemblies into agricultural machinery has profoundly impacted productivity.

5.1 Streamlined Operations

ECUs streamline various operations by coordinating activities between multiple systems, minimizing downtime caused by mechanical failures or inefficiencies.

5.2 Enhanced Data Analytics

With the ability to collect and analyze vast amounts of data, farmers can make informed decisions regarding field management, crop rotation, and resource allocation.

5.3 Scalability

As farming operations grow, the scalability of ECU technology allows for seamless integration with new machinery and equipment, ensuring that farmers can expand without losing efficiency.

6. Future Trends in ECU Technology for Agriculture

The future of ECU control box technology in agriculture is bright, with several emerging trends shaping the industry.

6.1 Increased Connectivity

As the Internet of Things (IoT) continues to evolve, the connectivity of ECUs with cloud-based platforms will enable farmers to monitor and control their machinery remotely.

6.2 Advanced Machine Learning

Machine learning algorithms can help improve the decision-making capabilities of ECUs by analyzing historical data and predicting future performance, leading to even greater efficiency.

6.3 Enhanced Cybersecurity

With the rise of connected devices comes the need for robust cybersecurity measures. Future ECUs will incorporate advanced security protocols to protect against potential threats.

7. Common Issues and Troubleshooting ECU Control Boxes

While ECU control box assemblies are robust, they can encounter issues. Understanding common problems can aid in effective troubleshooting.

7.1 Sensor Failures

Malfunctioning sensors can lead to incorrect data readings, impacting the overall performance of the machinery. Regular inspections and replacements are essential.

7.2 Software Bugs

Like any software-based system, ECUs may experience bugs. Regular updates and maintenance checks can help resolve these issues.

7.3 Communication Errors

Faulty connections between the ECU and other components can result in communication errors. Ensuring all connections are secure can mitigate this problem.

8. Conclusion

The ECU control box assembly plays a critical role in enhancing the efficiency and productivity of agricultural machinery. By leveraging advanced technology, farmers can optimize their operations, reduce costs, and promote sustainable practices. As agricultural demands continue to evolve, so too will the technology that supports it, with ECU assemblies remaining at the forefront of this transformation. Adopting these systems not only unlocks the potential for increased yields but also positions farmers to thrive in an increasingly competitive market.

9. FAQs about ECU Control Box Assembly in Agriculture

9.1 What is an ECU control box assembly in agricultural machinery?

The ECU control box assembly is an integral component of agricultural machinery that regulates and manages various operational functions, ensuring efficient performance through real-time data processing.

9.2 How does an ECU improve fuel efficiency?

The ECU monitors engine performance and adjusts fuel delivery based on real-time data, optimizing consumption and reducing costs.

9.3 What types of agricultural machinery utilize ECU control boxes?

ECU control boxes are used in a variety of equipment, including tractors, harvesters, and irrigation systems, among others.

9.4 How can I troubleshoot common ECU issues?

Regular inspections of sensors, software updates, and ensuring secure connections can help troubleshoot common ECU-related problems.

9.5 What are the future trends in ECU technology for agriculture?

Future trends include increased connectivity with IoT, advanced machine learning for improved decision-making, and enhanced cybersecurity measures to protect against threats.