Maximizing Performance: The Essential Role of Tractor Clutches in Heavy Machinery

Release time:

2025-05-20

Maximizing Performance: The Essential Role of Tractor Clutches in Heavy Machinery

Table of Contents

- Understanding Tractor Clutches

- Types of Tractor Clutches

- The Mechanics of Clutch Operation

- The Importance of Clutch Maintenance

- Optimizing Performance with Clutches

- Common Issues with Tractor Clutches

- The Future of Tractor Clutch Technology

- FAQs About Tractor Clutches

Understanding Tractor Clutches

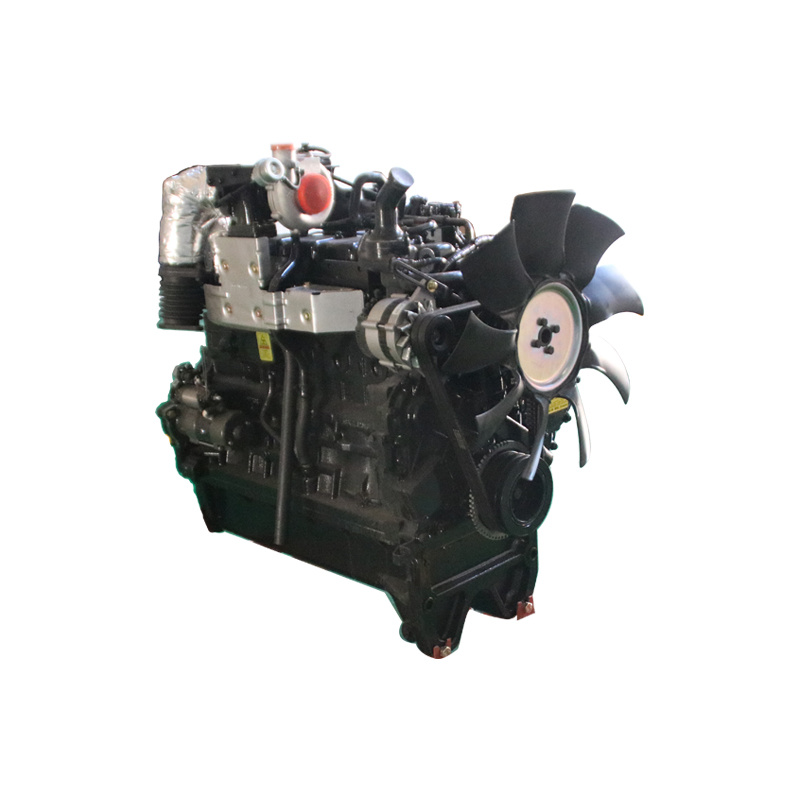

Tractor clutches play a critical role in the performance of heavy machinery. They serve as a connection between the engine and the drive train, allowing operators to control the power delivery efficiently. **Understanding how clutches function** will help you appreciate their importance in agricultural and construction equipment.

The Functionality of Clutches

At its core, a clutch allows for the engagement and disengagement of the engine’s power to the wheels. This process is essential for starting, stopping, and shifting gears effectively. Without a properly functioning clutch, the machine would face significant operational challenges, including stalled engines and difficulty in gear transitions.

Types of Tractor Clutches

There are several types of tractor clutches utilized in heavy machinery. Each type has unique features suited for different applications.

Friction Clutches

Friction clutches are the most common in tractors. They utilize friction plates to engage and disengage power. The surface area and material of the plates greatly affect performance, wear, and heat dissipation.

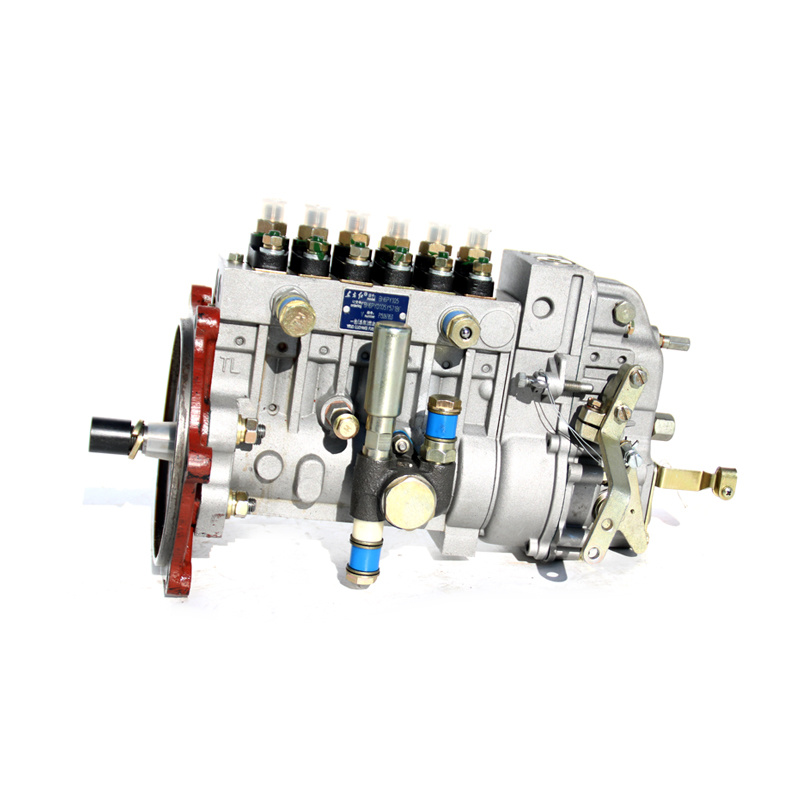

Hydraulic Clutches

Hydraulic clutches use fluid pressure to operate. They offer smooth engagement and disengagement, which is particularly beneficial in applications requiring fine control, such as in grading or tilling.

Electromagnetic Clutches

These clutches engage and disengage through electromagnetic forces. They are known for their rapid response times and precise control, making them ideal for automated systems.

The Mechanics of Clutch Operation

The operation of a tractor clutch involves a series of mechanical processes that convert engine power into usable force. Understanding these mechanics is vital for effective maintenance and operation.

The Engagement Process

When the clutch pedal is pressed, the connection between the engine and transmission is broken, allowing the operator to change gears without damaging the gears themselves. This **seamless transition** is crucial for maintaining momentum and control.

The Disengagement Process

Upon releasing the pedal, the clutch re-engages, transferring power back to the drive wheels. This process must be smooth to prevent sudden jerks, which can lead to equipment damage and operator discomfort.

The Importance of Clutch Maintenance

Regular maintenance is essential to ensure the longevity and efficiency of tractor clutches. Neglecting maintenance can lead to significant performance issues and costly repairs.

Signs of Wear and Tear

Some common indicators that your clutch may need attention include slipping, unusual noises, and difficulty in shifting gears. Addressing these issues promptly can prevent more severe damage.

Regular Inspections

Implementing a schedule for regular inspections can help catch potential problems early. During these inspections, check for wear on friction plates, hydraulic fluid levels, and any signs of leaks.

Optimizing Performance with Clutches

Maximizing the performance of your machinery involves more than just ensuring clutches are functioning; it requires understanding how to utilize them effectively.

Proper Usage Techniques

Operators should be trained in techniques that minimize wear, such as avoiding riding the clutch and ensuring smooth transitions between gears. Additionally, understanding the load capabilities of the clutch can help in selecting the right gear for specific tasks.

Upgrading Clutch Systems

Investing in high-performance clutches can greatly enhance machinery efficiency. Upgraded systems often provide better heat dissipation, increased durability, and improved responsiveness.

Common Issues with Tractor Clutches

Identifying common problems associated with tractor clutches can save time and money in the long run.

Slipping Clutch

A slipping clutch can occur due to worn plates or insufficient hydraulic pressure. This issue can lead to a loss of power transfer and should be addressed immediately to prevent further damage.

Hard to Shift Gears

If shifting gears becomes challenging, it may indicate a problem with the clutch linkage or hydraulic system, necessitating a thorough inspection.

The Future of Tractor Clutch Technology

The evolution of technology continues to shape the development of tractor clutches. Future advancements may include:

Smart Clutch Systems

As machinery becomes more automated, smart clutch systems that utilize sensors to monitor performance in real-time are likely to emerge. These systems can adjust engagement based on load and operational conditions.

Enhanced Materials

The development of new materials that offer better heat resistance and longevity will undoubtedly impact clutch design, leading to more robust systems that require less frequent maintenance.

FAQs About Tractor Clutches

What is the main function of a tractor clutch?

The main function of a tractor clutch is to connect and disconnect the engine from the drivetrain, allowing for smooth gear changes and improved control over machinery operations.

How often should tractor clutches be inspected?

Tractor clutches should be inspected regularly, ideally every 100 hours of operation or more frequently if signs of wear or malfunction are noticed.

What are the signs that a clutch needs replacement?

Signs include slipping, difficulty in engaging or disengaging gears, abnormal noises, and the smell of burning material.

Can the performance of a tractor be improved by upgrading the clutch?

Yes, upgrading to a high-performance clutch can enhance the efficiency, responsiveness, and durability of your tractor, ultimately improving overall productivity.

What maintenance practices are essential for tractor clutches?

Essential practices include regular inspections, keeping the clutch clean, monitoring fluid levels for hydraulic clutches, and replacing worn components timely.

Conclusion

Tractor clutches are indispensable in the realm of heavy machinery, significantly influencing performance, durability, and operator control. Understanding their function, types, and maintenance is crucial for anyone involved in operating or maintaining heavy machinery. By maximizing the capabilities of tractor clutches, you not only enhance performance but also contribute to the longevity and efficiency of your equipment. As technology continues to advance, staying informed about new developments in clutch systems will ensure you remain at the forefront of machinery operation and maintenance.