Discover Top Choices for the Best Diesel Filters in Agricultural Machinery

Release time:

2025-04-06

Discover Top Choices for the Best Diesel Filters in Agricultural Machinery

Table of Contents

- 1. Introduction to Diesel Filters in Agriculture

- 2. Importance of Diesel Filters in Agricultural Machinery

- 3. Types of Diesel Filters for Agricultural Equipment

- 4. Top Brands of Diesel Filters in Agricultural Machinery

- 5. Criteria for Choosing the Best Diesel Filters

- 6. Installation and Maintenance of Diesel Filters

- 7. Frequently Asked Questions

- 8. Conclusion

1. Introduction to Diesel Filters in Agriculture

In the realm of agricultural machinery, diesel filters play a vital role in ensuring optimal performance and longevity of equipment. Whether you're operating tractors, harvesters, or irrigation systems, understanding the importance of high-quality diesel filters is crucial. This article will explore the top choices available, focusing on performance, reliability, and price.

2. Importance of Diesel Filters in Agricultural Machinery

**Diesel filters** are essential components of agricultural machinery as they serve to clean the fuel before it reaches the engine. Contaminants such as dirt, water, and debris can cause significant damage to the engine, leading to costly repairs and downtime. By investing in quality diesel filters, farmers can ensure:

- **Improved Engine Performance:** Clean fuel promotes efficient combustion, resulting in better horsepower and torque.

- **Longevity of Equipment:** Protecting the engine from contaminants extends its lifespan and reduces the need for replacement.

- **Fuel Efficiency:** A well-functioning diesel filter helps maintain optimal fuel flow, leading to improved fuel economy.

- **Reduced Downtime:** Regularly replacing filters minimizes the risk of unexpected breakdowns in the field.

3. Types of Diesel Filters for Agricultural Equipment

Understanding the different types of diesel filters available can aid in selecting the right filter for your agricultural machinery. The main types include:

3.1 Primary Fuel Filters

These filters are the first line of defense against contaminants. They are typically installed close to the fuel tank and designed to remove large particles.

3.2 Secondary Fuel Filters

Secondary filters are finer and provide an additional layer of filtration. They filter out smaller particles that may have passed through the primary filter.

3.3 Water Separators

Water separators are essential for removing moisture from diesel fuel. Water contamination can cause serious engine problems, making these filters critical for machinery operating in damp conditions.

3.4 Fuel/Water Separator Filters

These filters combine both functions, filtering out debris and separating water from diesel fuel, making them a comprehensive solution for protecting engines.

4. Top Brands of Diesel Filters in Agricultural Machinery

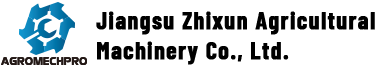

Several brands are renowned for manufacturing high-quality diesel filters designed specifically for agricultural machinery. Here are some of the top choices:

4.1 Fleetguard

Fleetguard filters are known for their robust design and excellent filtration performance. They offer a range of options tailored for various agricultural applications, ensuring optimal protection for engines.

4.2 Baldwin Filters

Baldwin Filters provide reliable filtration solutions with a focus on durability. Their filters are designed to withstand harsh operating conditions typical in agricultural settings.

4.3 WIX Filters

WIX Filters is a trusted name in the industry, known for its innovative designs and comprehensive product range. They offer filters that ensure high performance and engine safety.

4.4 Donaldson

Donaldson filters are recognized for their advanced filtration technology. Their products are engineered to meet the specific needs of agricultural machinery, promoting efficiency and reliability.

4.5 Mann-Filter

Mann-Filter products are synonymous with quality and performance. Their diesel filters are designed to keep engines running smoothly, ensuring optimal fuel flow and engine protection.

5. Criteria for Choosing the Best Diesel Filters

When selecting diesel filters for agricultural machinery, several criteria should be considered to ensure the best choice:

5.1 Filtration Efficiency

Look for filters with high filtration efficiency ratings. The ability to capture small particles is crucial for protecting sensitive engine components.

5.2 Compatibility

Ensure the diesel filter is compatible with your specific machinery model. Using the wrong filter can lead to suboptimal performance and potential damage.

5.3 Durability

Select filters made from high-quality materials that can withstand the rigors of agricultural environments. Durability translates to longer service life and reduced replacement frequency.

5.4 Ease of Installation

Choose filters that are easy to install, as this can save time and reduce labor costs during maintenance.

5.5 Cost-Effectiveness

While price is an important factor, focus on the overall value. A higher-quality filter may have a higher upfront cost but can save money in the long run by preventing costly repairs.

6. Installation and Maintenance of Diesel Filters

Proper installation and maintenance of diesel filters are crucial for ensuring their effectiveness. Here are some essential tips:

6.1 Installation Process

- **Turn off the Engine:** Always start with the engine off to ensure safety.

- **Locate the Filter:** Identify the location of the old filter and remove it carefully.

- **Install the New Filter:** Follow the manufacturer’s instructions for installation, ensuring a tight seal to prevent leaks.

6.2 Regular Maintenance

- **Monitor Performance:** Keep an eye on engine performance and replace filters as recommended by the manufacturer.

- **Check for Contaminants:** Regularly inspect the fuel system for any signs of contamination.

- **Replace Filters on Schedule:** Adhere to a maintenance schedule for filter replacement, as outlined in the owner’s manual.

7. Frequently Asked Questions

7.1 How often should I replace my diesel filters?

It is recommended to replace diesel filters every 500 to 1,000 hours of operation, but always check the manufacturer's recommendations for your specific machinery.

7.2 Can I use aftermarket diesel filters?

Yes, aftermarket filters can be used, but ensure they meet OEM specifications to maintain engine performance and warranty.

7.3 What are the signs of a clogged diesel filter?

Signs of a clogged diesel filter include reduced engine power, difficulty starting, and increased fuel consumption.

7.4 Is it necessary to use water separators?

Yes, water separators are essential, especially in regions with high humidity or where water contamination is common.

7.5 Can diesel filters affect fuel efficiency?

Absolutely. A clean, high-quality diesel filter promotes optimal fuel flow and combustion, directly impacting fuel efficiency.

8. Conclusion

Selecting the best diesel filters for agricultural machinery is essential for maintaining performance and longevity. By understanding the types, brands, and criteria for choosing filters, farmers and operators can make informed decisions that enhance their machinery's effectiveness. Whether it’s ensuring clean fuel or reducing the risk of breakdowns, investing in quality diesel filters ultimately leads to a more successful agricultural operation. Remember, the right filter not only protects your engine but also saves both time and money in the long run.